SINCE 1993 MADE IN USA | ISO 9001:2015 | Call Us: 303.684.0931

SINCE 1993 MADE IN USA | ISO 9001:2015 | Call Us: 303.684.0931 SINCE 1993 MADE IN USA | ISO 9001:2015 | Call Us: 303.684.0931

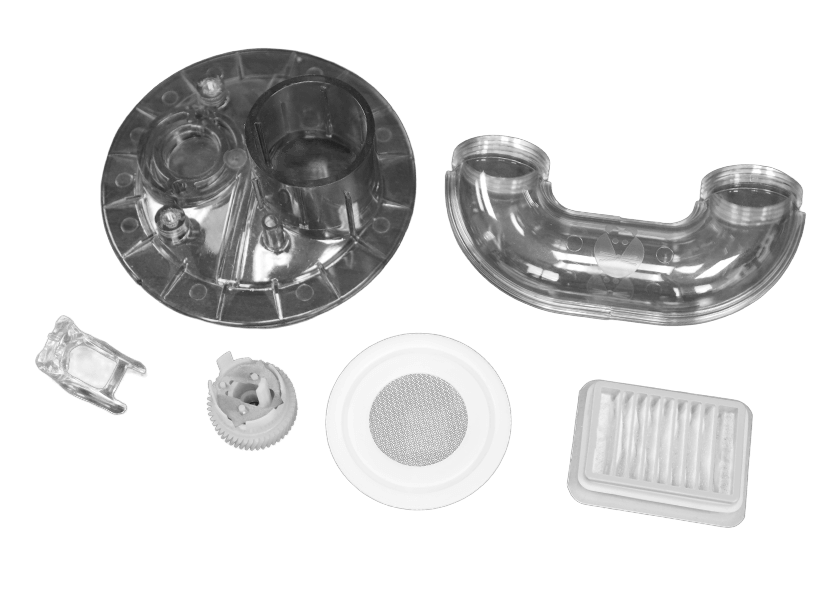

SINCE 1993 MADE IN USA | ISO 9001:2015 | Call Us: 303.684.0931Injection molding is a complex manufacturing process used to produce large volumes of plastic parts with high precision and accuracy. This process involves injecting molten plastic into a metal mold, where it cools and solidifies to form the desired shape. Widely used across various industries, including automotive, medical devices and consumer goods, injection molding is known for its ability to create complex shapes and designs efficiently.

One of the key advantages of injection molding is its cost-effectiveness, making it a popular choice for mass production. The multiple process stages include mold design, material selection and manufacturing. Each stage requires specialized equipment, like injection molding machines and molds. This versatile process can produce a wide range of plastic products, from simple components to intricate assemblies.

As technology and materials advance, the injection molding process continues to evolve, leading to improved efficiency and quality. This evolution makes injection molding an essential part of modern manufacturing, enabling the production of high-quality plastic parts with precision and accuracy.

An injection molding machine is a sophisticated piece of equipment essential for producing plastic parts through the injection molding process. The machine comprises several key components, including the injection unit, clamping unit and control system. The injection unit is responsible for melting and injecting the plastic material into the mold, while the clamping unit holds the mold in place and applies the necessary pressure to ensure proper molding.

The control system regulates the machine’s functions, such as temperature, pressure and speed, ensuring optimal performance. Injection molding machines come in various sizes and capacities, from small benchtop models to large industrial machines, catering to different applications and types of plastic materials.

Modern injection molding machines often feature advanced technologies, including computerized controls and robotic automation, enhancing efficiency and precision. Regular maintenance and machine upkeep are critical practices to prevent downtime and ensure consistent, high-quality production. A technical understanding of the injection molding machine optimizes the manufacturing process, resulting in top-notch plastic parts.

Key components of the mold include the mold cavity, core and runner system. The mold cavity is the space where the plastic material is injected and forms the shape of the part, while the core helps create the part’s shape and features. The runner system is a network of channels that delivers the plastic material to the mold cavity.

Computer-aided design (CAD) software is often used to create and simulate the mold design, allowing for optimization through techniques like finite element analysis and mold flow simulation. A well-designed injection mold is essential for producing high-quality plastic parts with precision and accuracy, cementing the mold design as a critical foundational step for the entire injection molding process.

The injection molding process begins with the critical step of designing the mold itself. Among the variables up for consideration, the mold design must account for:

The plastic injection molding machine is a complex piece of equipment designed to produce high-quality plastic parts. The machine's efficiency largely depends on the proper functioning of its components. It begins with heater bands that heat the barrel and screw to melt plastic pellets. This heating process must thoroughly melt the plastic into a molten state to facilitate its injection into every part of the mold. Next, the barrel screw applies pressure to the molten material during the injection phase, aiding its transition from the barrel into the mold cavity. This optimizes molded product density in an efficient manner. Additionally, maintaining pressure during the holding stage is important to prevent backflow and compensate for material shrinkage.

The design of the injection mold is fundamental to the success of the injection molding process. The mold cavities form the shape of the part as the molten material is injected at high speed and high pressure into these cavities. This process requires careful consideration of the material flow and cooling rates to ensure the final product meets the desired specifications. Ensuring that the mold core and cavity fit together perfectly is essential for achieving tight tolerances and high-quality finishes. Proper grinding and polishing of these components are necessary before the injection molding process begins.

The cooling process is an essential next step to prevent deformation of the molded product. During this stage, the plastic solidifies before being ejected from the mold.

The ejector rod plays an important role in the injection molding process by releasing products from the mold after cooling. Once ejected, the parts drop onto a conveyor belt where additional finishing processes may occur before the components are prepared for distribution.

The final step in the injection molding process determines whether the part meets client specifications for form and function. The inspection stage examines the quality and consistency of the molded parts to ensure the highest standards are being met during production. A meticulous examination helps the manufacturing team identify and rectify any defects, if present. This attention to detail enhances the efficiency of the production process while also guaranteeing that the molded parts meet the required quality standards.

Injection molding is a versatile process with a wide range of applications across various industries, and each injection molding company has developed unique areas of expertise. For example, the medical field relies on injection molding to manufacture precision components for medical devices, including multi-cavity parts requiring extremely tight tolerances and specialized components like charger bases for medical equipment.

Injection molding creates many components used in the electronics industry, such as connectors, filters, electronic circuits, small enclosures, standoffs and brackets. These components typically require high insulation properties to protect sensitive circuitry, though specialized applications may require conductive plastics for static discharge protection.

The agricultural sector utilizes injection-molded parts for lightweight components in agricultural equipment that resist environmental conditions. The food manufacturing industry relies on injection-molded parts that meet stringent FDA and EU regulatory standards for hygiene, safety, and non-toxicity, particularly when components may come into contact with food products.

Finally, injection molding enables metal replacement solutions for many industrial applications, where advanced plastics can meet the mechanical requirements of components that were traditionally manufactured from metal.

Injection molding is a complex process that can be affected by several challenges and variables. One of the most common challenges is ensuring proper mold design and construction, as the mold must withstand the high pressures and temperatures involved in the injection molding process. Selecting the right plastic material for the application is also a critical factor, with various polymers available depending on desired properties such as strength, flexibility and chemical resistance.

The process can be affected by issues like warping, shrinkage and sink marks, which can compromise the quality of the final product. Maintaining optimal processing conditions, including temperature, pressure and speed, is essential for producing high-quality parts. Material property variations, such as viscosity and thermal conductivity, can also impact the process.

Successful injection molding requires ongoing attention to both equipment and environment. Regular maintenance schedules keep machines running smoothly and extend mold life, while proper climate control prevents material degradation and processing inconsistencies. Temperature fluctuations can cause warpage, while excessive humidity may lead to surface defects or compromised material properties.

Mastering injection molding demands a multidisciplinary approach—combining engineering precision in mold design with scientific understanding of polymer behavior and practical expertise in process control. The most successful operations integrate these elements seamlessly, turning potential obstacles into opportunities for innovation and efficiency gains.

Get started today

Setting injection molding parameters involves adjusting temperature, pressure, speed and cooling time based on the specific plastic material and part design requirements. Key parameters include:

AIM Processing optimizes its injection molding process steps through strategic use of control systems combined with a highly skilled and experienced team. The team at AIM Processing maintains proper conditions and adheres to the highest quality standards to produce parts with precision and accuracy.

Outsourcing manufacturing overseas can deliver initial cost savings, but quality issues often erode those gains. Even with lower-cost hand assembly, ...

Read MoreGreat plastic parts don’t emerge from the press unless they first start at the design desk. The injection molding industry is entering a new era. ...

Read MoreAs a manufacturing manager, you know the frustration: Parts arriving with inconsistent quality. Missed delivery deadlines. Phone calls and emails ...

Read More“We received the charger base and I want you all to know it looks FANTASTIC! Thank you for getting us this one for the BOD meeting.”

Joe P., President,

medical device company

“…thanks for all of your hard work as well as others at your facility in making this happen.”

Ron H., Quality Control Manager,

industrial product company