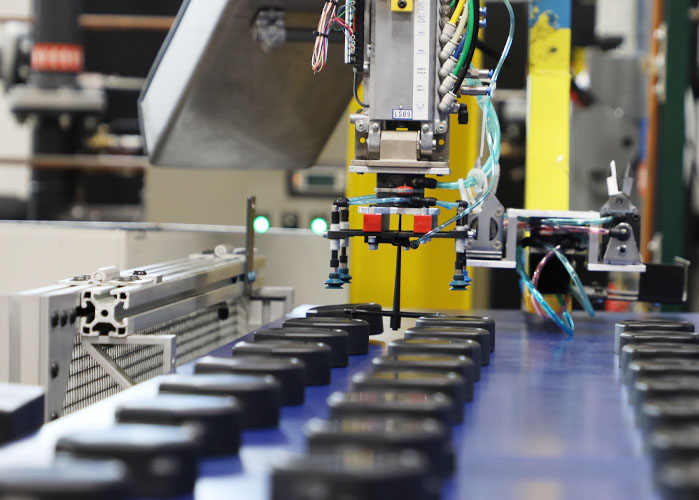

Mold costs vary widely depending on complexity, size, cavity count and precision requirements. AIM Processing's injection molding service takes a project-specific approach to toolmaking, allowing customers to leverage specialized toolmaker expertise that optimizes both quality and cost-effectiveness.

SINCE 1993 MADE IN USA | ISO 9001:2015 | Call Us: 303.684.0931

SINCE 1993 MADE IN USA | ISO 9001:2015 | Call Us: 303.684.0931