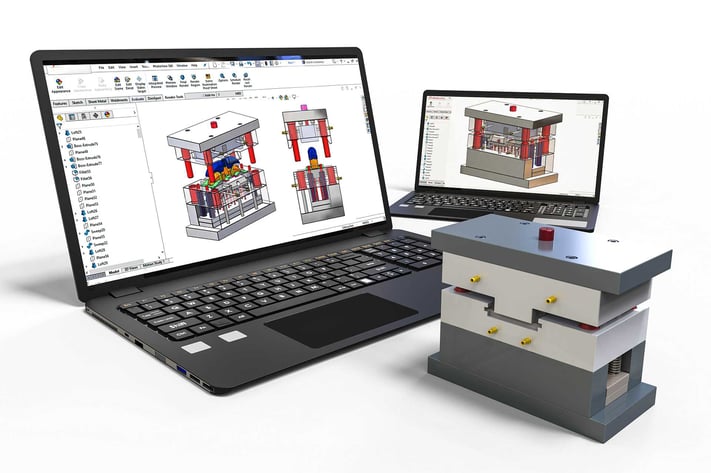

CAD modeling software and 3-D printing has sped up new product development and enabled all kinds of people to transition their concept from the whiteboard or the cocktail napkin to a tangible piece that they can test. Once the prototype phase is complete, the focus turns to making the product manufacturable in volume and one of the common manufacturing methods is injection molding. But injection molding has design requirements that differ from other prototyping methods.

After having spent so much time developing the concept, going backwards in the design phase to accommodate injection molding can be frustrating. AIM’s goal is to always position ourselves as a thoroughly transparent company in our industry. Because of that, we have put together a selection of custom injection molding topics that can help prepare you for what’s ahead. If you are interested in learning more about our industry, we invite you to read on:

CAD models only show cosmetically perfect parts

The renderings in your CAD software shows the perfect part. It’s flat if you want it flat, round if you want it round. It’s thick if you want it thick. The surface is smooth and without flow lines or gate blush. No mold parting line or flash. No burn marks from superheated air that is trapped into the tool. It is every bit as flawless as you imagined.

This is not to say that injection molding can’t help you achieve the part as you imagine. But your injection molder should have a thorough design discussion with you to ensure that the tool, the most expensive part of the process, is built to your expectations. Discovering a requirement after the tool is built could mean starting over, which is as financially painful as it is devastating to your schedule. Luckily for our customers, AIM is a leading expert in the industry, meaning that we have a thorough understanding of these types of mistakes and have a process in place to avoid these pitfalls of manufacturing.

Not all tools are equal

There are different classes of tools, aligned with their required longevity, and they have different build standards. That can be tough to distinguish, because it ultimately comes down to “craftsmanship” which is hard to distinguish in person and impossible to see in an emailed quote. Obtaining a quick-turn tool does you little good if you plan to go into production and it falls apart in month 2 because too many corners were cut. A budget tool may save you $2000, but what if you have to rebuild it in 6 months because there is flash everywhere? This can make it difficult to compare vendors and quotes, particularly if you are just starting out and don’t have a lot of experience. Commonly, simple cost can be a tempting metric for vendor evaluation, but it might not always be the best choice for you in the long run.

AIM Processing doesn’t build tools in-house. Instead, it works with a variety of domestic and offshore toolmakers to help build the tool that is best for your needs: budget, timing, durability, and precision. We think this is a better model for our customers.

Thicker isn’t always better

When starting out with a new plastic project, people are often looking for some level of rigidity. The common solution is to throw more plastic at it and make it thicker. That can work in some cases, but it isn’t always the best solution. Thicker parts consume more plastic volume, which increases cost. Thicker parts take longer to cool, which extends the cycle time, reduces output per hour, and increases cost. Further, areas of thick and thin in a part can create issues with sinks in thick sections and shorts in thin sections.

Instead of a thicker cover, consider making the wall thickness thinner and adding ribs on the inside. This has the benefit of reducing plastic volume and cycle time, which leads to a product that is just as strong but costs less. AIM Processing has experience with hundreds of enclosures and can help with design guidelines to make your part strong.

Don’t let your plastic choice put you in a corner

There are well over 100,000 grades of plastic resin for a reason: they are different. Some are better for chemical resistance, electrical resistance, flame/burn resistance. Some hold their dimensions more consistently. Some are suitable for medical/food environments. Some are suitable for high temperature exposure. Some are more UV resistant. Lastly, some cost less. When you are developing a product, the performance of the plastic may be the last thing you’re thinking about. So, you might be thinking, no big deal – we could just switch later.

Plastics shrink at different rates, so this means that a tool designed for one material can give you a different sized part if you change materials. Some plastic families will have similar shrink rates as others. But if you suddenly discover you have a chemical resistance problem, you might find that you don’t have similar shrink-rate, chemical-resistance plastics to choose from. Different plastics may have different tool draft requirements. If you’re at this point, you might need to remake your tool.

It is for this reason that it is crucial to work with a molding company that has a thorough understanding of the molding attributes of a wide variety of plastics. However, even with a highly knowledgeable manufacturer, changing mold designs to accommodate material changes mid-production will typically result in additional costs and longer production times, so it can be beneficial to discuss project details extensively with your custom injection molding partner before the full production run begins.

3-D printing can make some pretty impossible parts

Injection molding has a few design aspects that differ from 3-D printing. Injection molding generally involves a tool or mold that is held closed under pressure while plastic is injected into the tool. When the cycle is complete, the mold splits open with one moving side, the part is ejected, and the cycle repeats. To make this magic happen, the part can have undercuts or side holes, but those require features that must move out of the way. This is possible, but it can increase tooling cost and they must be designed for your needs. Another requirement for injection molding is draft. When the part is ejected from the moving side of the tool, draft is what enables the part to move cleanly off the tool. Being aware of these differences can help you make the transition to injection molding.

Injection molding does have some guidelines that differ from 3-D printing, but they are fairly simple. If you’ve made it this far, you’re close. Let AIM Processing help you move from your concept or prototype to production.

Need More Insider Information Regarding Custom Injection Molded Parts? Contact the AIM team Today!

As you can see, AIM is dedicated to answering our customers' questions. If you are looking for a knowledgeable source of industry information, look no further— AIM is a responsive custom injection molding company that is eager to be of service.

SINCE 1993 MADE IN USA

SINCE 1993 MADE IN USA