Great plastic parts don’t emerge from the press unless they first start at the design desk.

Design for Manufacturability: Optimizing Your Part for Injection Molding Success

Posted: September 30, 2025 by

Jon Gelston

Tags:

Plastic Injection Molding

Tooling Transfer: Breaking Free from Underperforming Injection Molders

Posted: April 14, 2025 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Injection Molding Defects,

Tool Transfer

As a manufacturing manager, you know the frustration: Parts arriving with inconsistent quality. Missed delivery deadlines. Phone calls and emails going unanswered. Yet despite these issues, many managers feel trapped with their current injection molding partner because they possess the tooling needed to produce critical parts.

Three Tricks for Successful Demolding in Plastic Injection Molding

Posted: March 21, 2025 by

Jon Gelston

Tags:

Plastic Injection Molding,

Quality

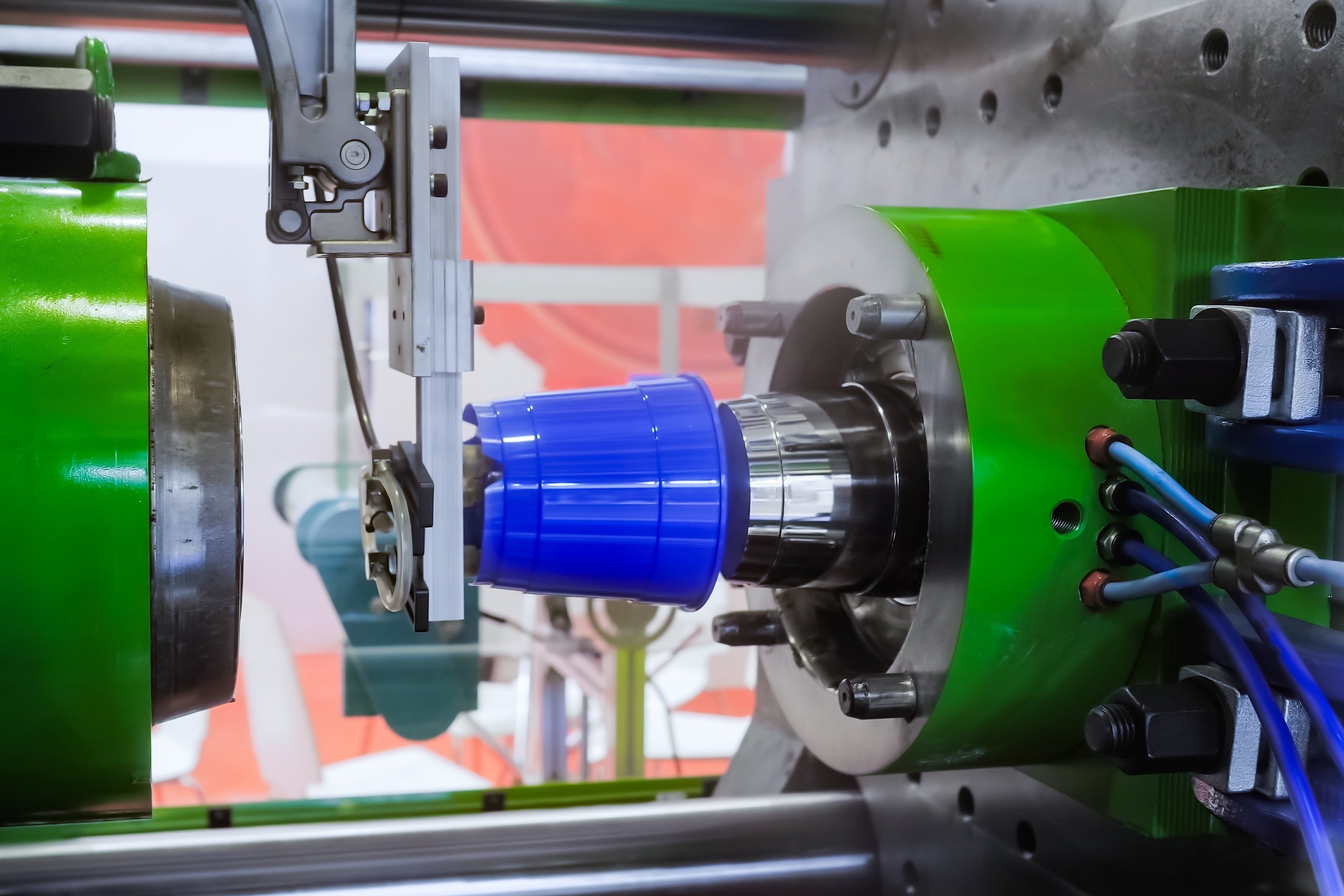

In plastic injection molding, the process of demolding a part is as important as creating the mold design and forming the part. Successful demolding is essential for maintaining part quality, reducing mold damage and minimizing cycle times. To optimize the process, here are three crucial tricks to enable a clean release from the mold without creating defects in the part. These recommendations will generate more consistent and efficient demolding.

Sinking in Sink Marks?

Posted: February 10, 2025 by

Jon Gelston

Tags:

Plastic Injection Molding,

Plastic Injection Molding Defects,

Quality

How to avoid them and produce high-quality injection molded parts

Injection molding creates complex plastic parts with high precision and repeatability. However, like any manufacturing process, it comes with its challenges, including defects in the molded part. One of the most common defects is sink marks. These small surface depressions can compromise not only the aesthetic appeal of a product but also its functionality. This blog will describe sink marks, explain what causes them to occur and offer methods to prevent these defects.

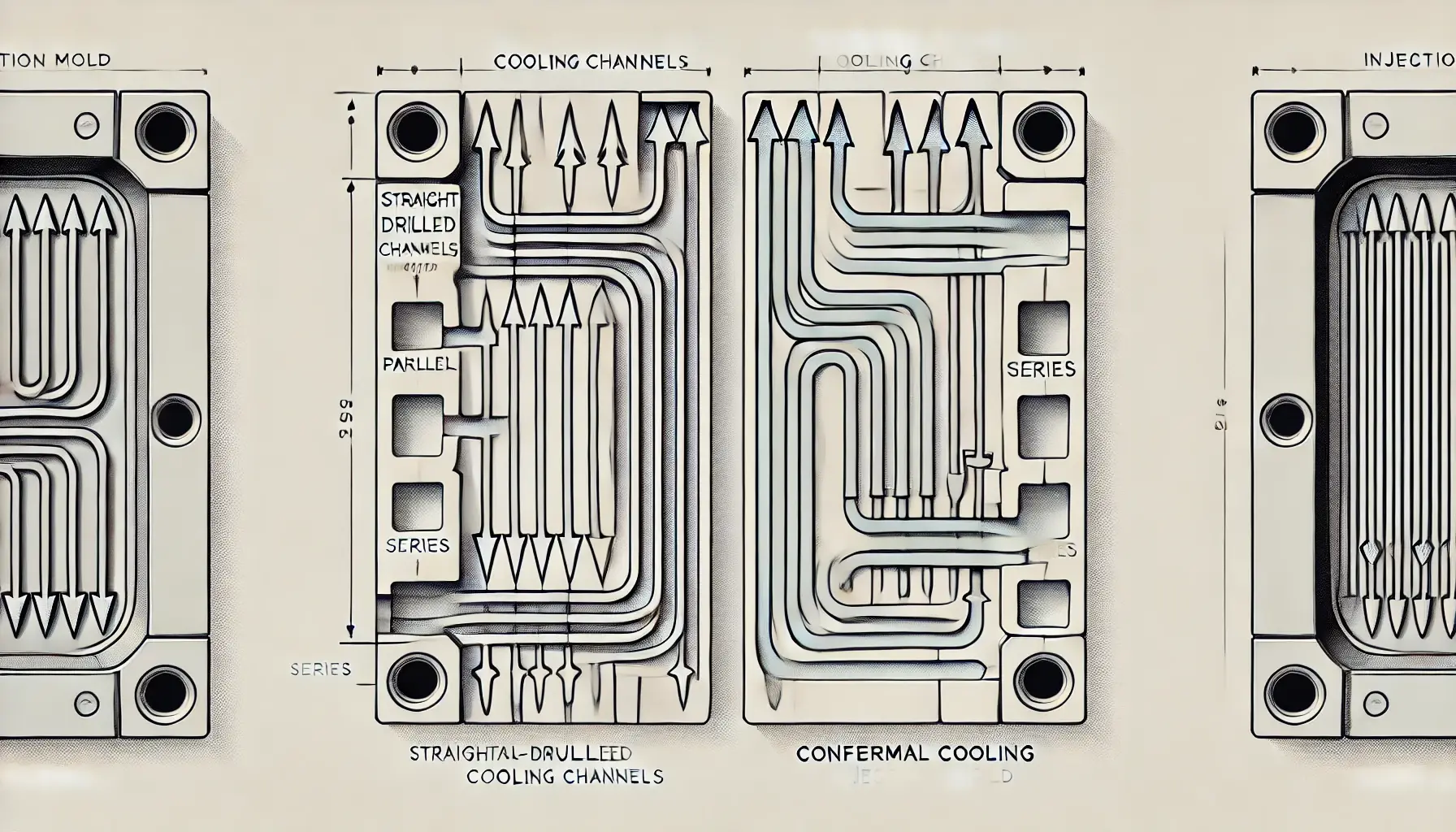

Designing Cooling Channels in Injection Molds: A Combination of Art and Science

Posted: December 4, 2024 by

Jon Gelston

Tags:

Plastic Injection Molding,

Quality,

injection molding

Cooling the molten plastic injected into the mold in a plastic injection molding machine is a critical process. The cooling system controls the temperature of the mold and impacts the quality and forming efficiency of the injection molded product. Uneven temperatures in the mold create temperature differentials in different sections of the product. The varying temperature across the product can cause temperature-induced stress, shrinkage, warping and deformation. Products with complex shapes and uneven wall thickness are particularly susceptible to these effects if the temperature distribution is uneven. An efficient cooling system that can maintain a uniform temperature distribution can minimize these defects in the molded parts. This article will present both options and recommendations for designing effective cooling channels in injection molds and explore strategies and considerations crucial for maximizing cooling efficiency and optimizing molding outcomes.

Voice of the Customer: Empowering Medical Device Innovation Through Precision Manufacturing

Posted: October 29, 2024 by

Jon Gelston

Tags:

Plastic Injection Molding,

Quality,

Tool Transfer,

Customer

A minimally invasive medical procedure or device simplifies traditional treatment methods, causing the patient less pain and reducing the risk of complications. When Trice Medical was experiencing unnecessary complications and frustrations obtaining critical injection molded components for its manufactured equipment, it realized the need for a new business partner that could supply a reliable, painless solution. Recently, President of Trice Medical, Mike Steen, sat down to discuss his company's long-standing partnership with AIM Processing. With more than 15 years of experience in the industry, Mike shared valuable insights into the strong collaboration between the two companies, the value AIM Processing brings to the table and how their partnership has evolved over time.

How To Avoid Warping and Shrinkage in Injection Mold Design

Posted: October 22, 2024 by Jon Gelston

Injection molding is one of the most common methods used in manufacturing plastic components. It allows for the production of intricate and highly detailed parts at high volumes. However, like any other manufacturing process, it presents several challenges. Two of the most prevalent issues encountered are warping and shrinkage. These defects can affect the overall quality of the molded part and even lead to part rejection if not properly managed. Understanding how to prevent warping and shrinkage in injection mold design is essential to maintaining high-quality production standards.

AIM Processing Expands Its Reach in Custom Injection Molding

Posted: September 23, 2024 by

Jon Gelston

Tags:

News

AIM Processing has acquired Technical Molded Products, solidifying its position as a leading injection molder in the western United States.

How to Size Minimum Wall Thickness for Injection Molding – Optimizing Your Part Designs

Posted: August 12, 2024 by

Jon Gelston

Tags:

Electronic Enclosures,

Quality,

Plastic vs. metal,

Waterproofing,

Outdoor enclosures

Maintaining proper wall thickness is one of the most important aspects of designing custom injection molded parts. Overly thick walls not only waste material, they’re also more likely to exhibit part defects such as sink marks. On the other hand, overly thin walls are prone to warping and cracking, while also generally lacking the strength necessary for a durable end product.

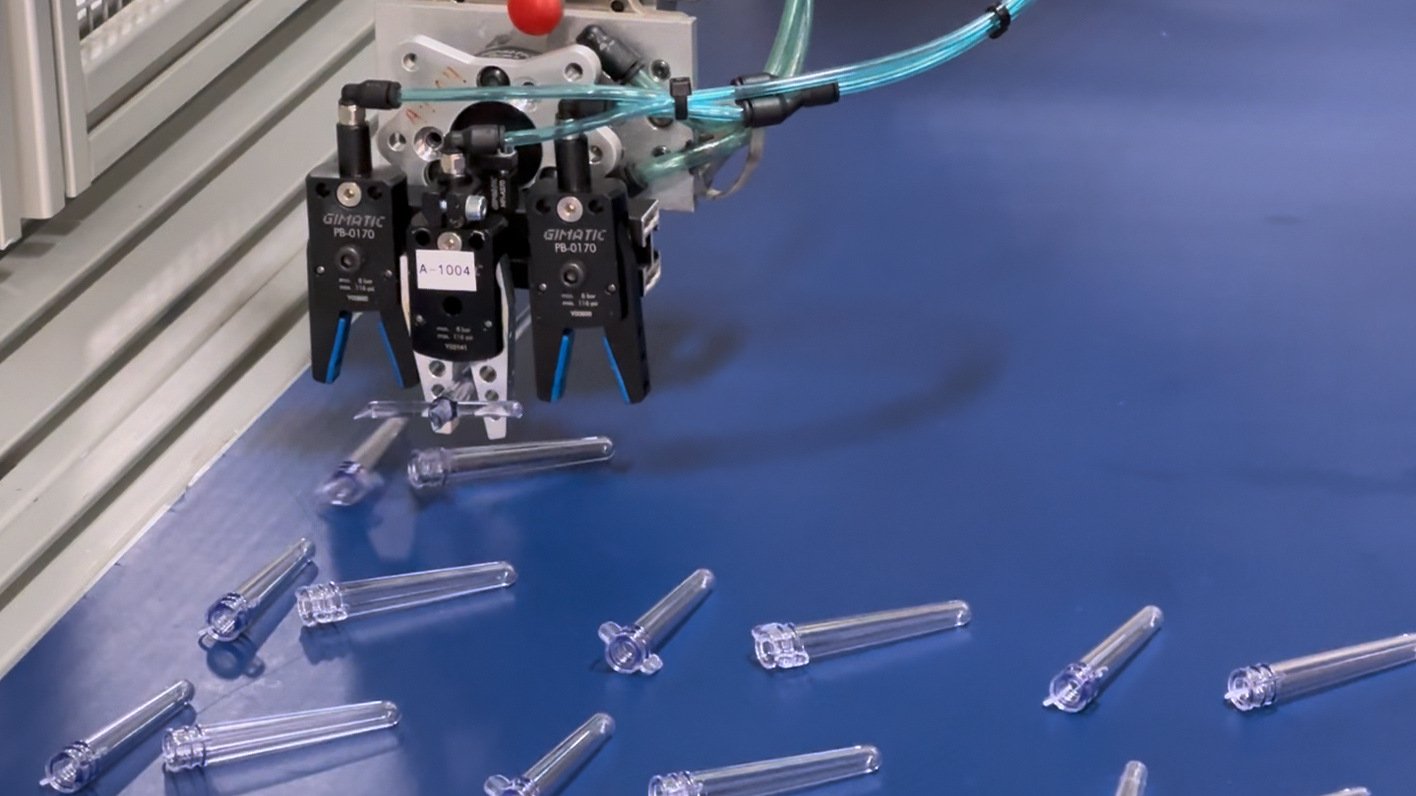

The Role of Automation in Modern Plastic Injection Molding

Posted: July 30, 2024 by

Jon Gelston

Tags:

Electronic Enclosures,

Quality,

Plastic vs. metal,

Waterproofing,

Outdoor enclosures

In the plastics manufacturing industry today, automation is the name of the game if you want to be competitive. Automated injection molding machines, robotic part handlers, automatic loading/unloading systems… In fact, automated manufacturing technology has become increasingly common throughout the American manufacturing sector as a whole. Essentially, these newer technologies help US manufacturersoperate as lean, efficient and productive as possible, thus meeting the new demands of onshoring while remaining cost competitive to the global marketplace.

SINCE 1993 MADE IN USA

SINCE 1993 MADE IN USA