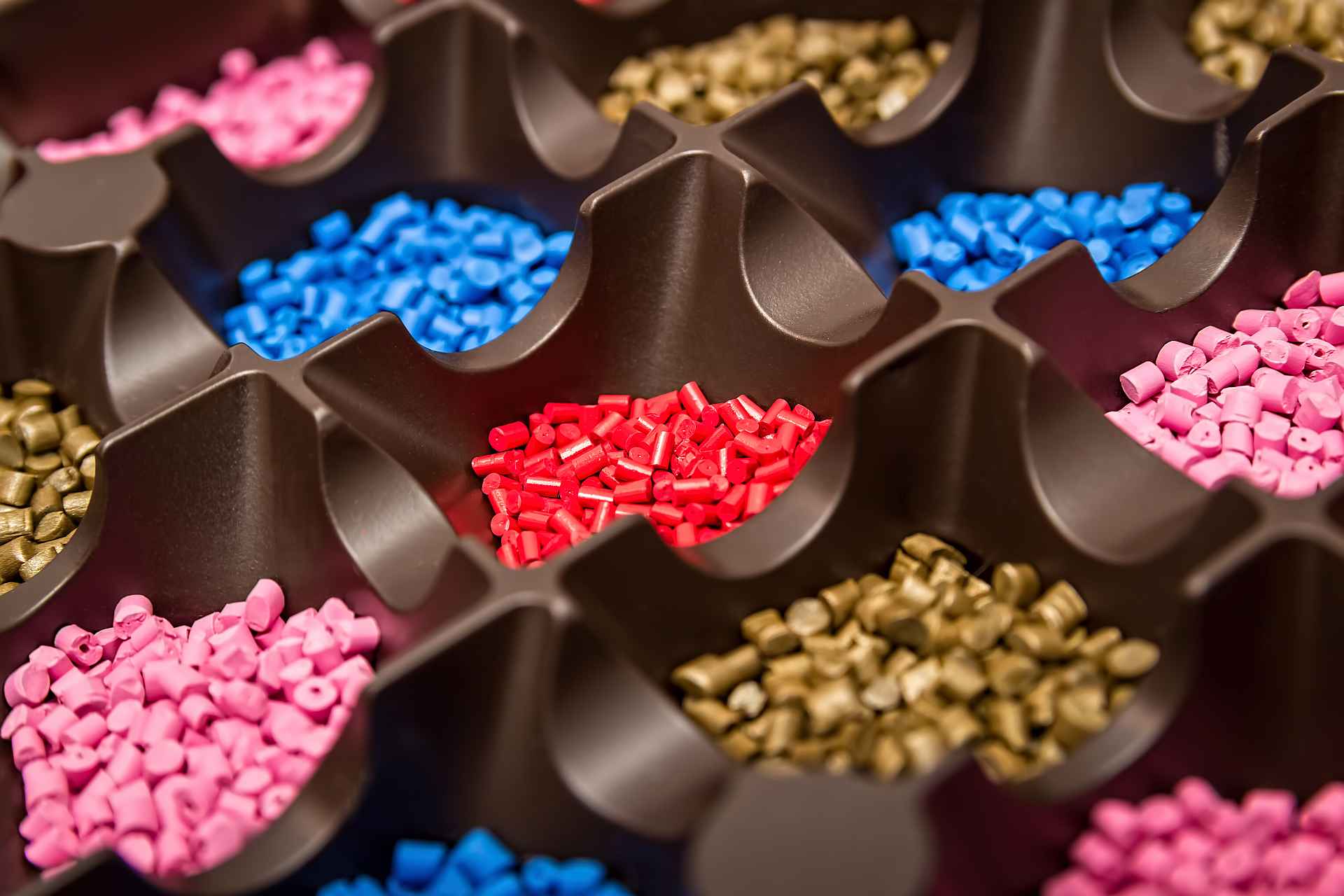

When it comes to designing custom injection molded products, choosing the right material is crucial. Optimum material choice ensures that the final products exhibit the quality and durability that you expect, as well as all of the desired performance aspects. Product costs are also often a major consideration in material choice.

Of course, there are a multitude of different injection molded plastics to choose from, each offering unique strengths and performance advantages. However, choosing the ideal molded plastic material isn’t always an obvious process. There are many complex material properties and production issues to consider.

SINCE 1993 MADE IN USA

SINCE 1993 MADE IN USA