Why Did That Happen? Common Problems With Threaded Inserts in Plastic

Posted: June 20, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

insert molding,

Plastic Types,

Quality,

Plastic vs. metal,

Choosing the right plastic injection molder

A Rookie's Guide to Threaded Inserts for Plastic, Injection Molding, & More

Posted: June 1, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

insert molding,

Plastic Types,

Quality,

Plastic vs. metal,

Choosing the right plastic injection molder

Essential Guide to Custom Injection Molding

Posted: March 15, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

elastomeric overmolding,

insert molding,

Plastic Injection Molding Tooling,

Plastic Types,

Small Plastic Parts,

Choosing the right plastic injection molder

Creating Complex Parts With Overmolding and Insert Molding

Posted: February 25, 2022 by

Jon Gelston

Tags:

Plastic Injection Molding,

elastomeric overmolding,

insert molding,

Plastic Injection Molding Tooling,

Plastic Types,

Small Plastic Parts,

Choosing the right plastic injection molder

Insert Molding: Tips for Holding the Part in Place

Posted: December 26, 2016 by

Jon Gelston

Tags:

insert molding

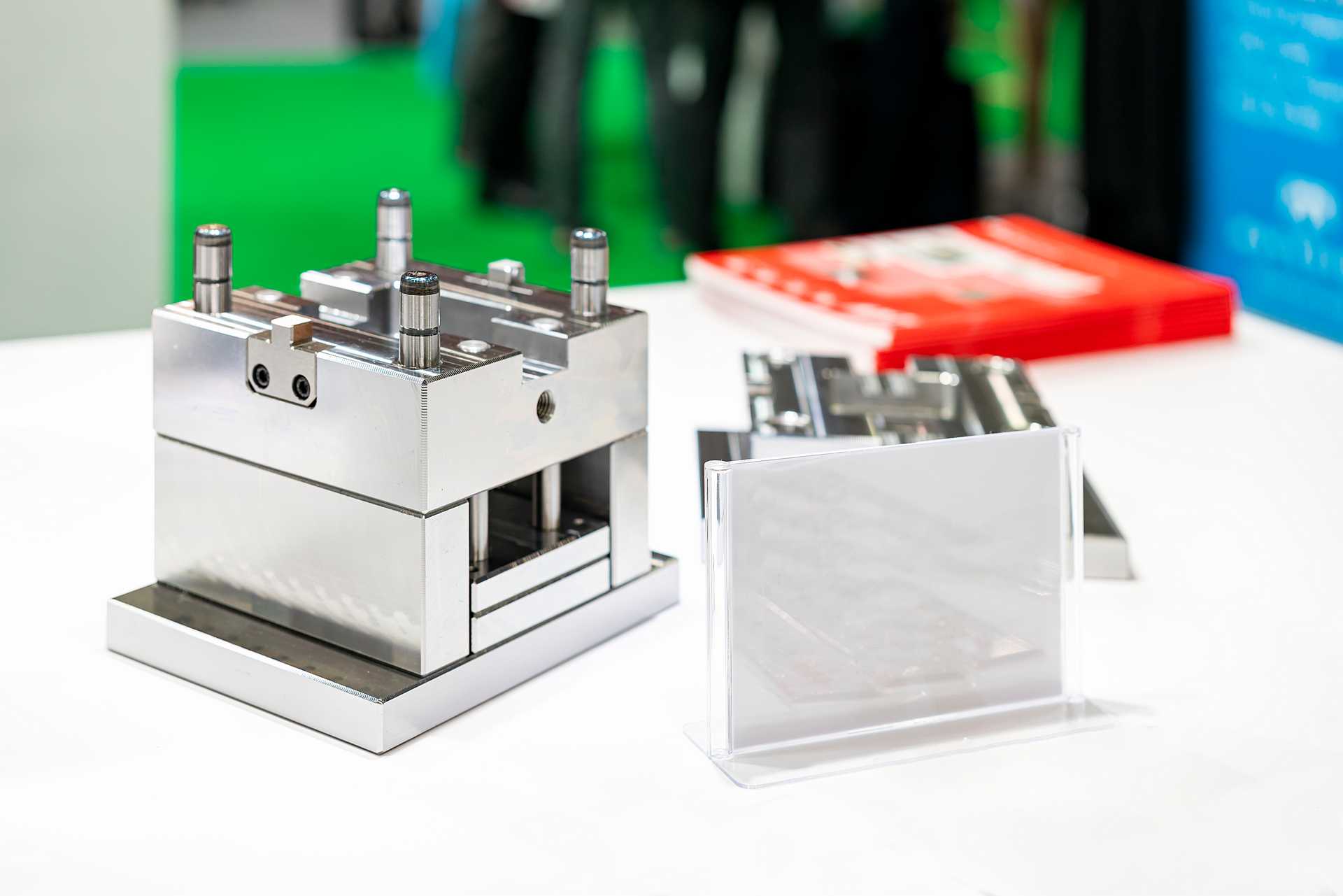

Insert molding is a technique in which an item such as a threaded fastener, tube or stud, electrical component, or label is present in the mold. As the viscous plastic fills in around it and hardens, the item becomes a component of the finished part. When performing insert molding, it’s obviously critical that the insert does not move as the mold closes or as plastic is injected under pressure into the cavity — no small feat as hot resin can enter at 20k-30k psi.

A Quick Introduction to Insert Molding

Posted: May 10, 2016 by

Jon Gelston

Tags:

Plastic Injection Molding,

insert molding

Insert molding, or more accurately “plastic injection insert molding,” is a process in which viscous plastic is injected into a mold around one or more items. When the plastic cools and hardens, the result is an integrated assembly that incorporates these “inserts.” The items can be metal, ceramic, or any other type of material that can withstand the heat of the melted plastic and the pressure with which it is injected into the mold.

SINCE 1993 MADE IN USA

SINCE 1993 MADE IN USA .jpg)